Geek+ drives automation of advanced BMW-producing plant in China

Geek+ brings its AMR expertise to premium car manufacturer BMW Brilliance Automotive's vehicle production facility to strengthen digitalization and end-to-end value chain.

Embracing Automation Technologies to Optimise Just-in-Time Processes

As businesses' priorities evolve as a means to navigate today's challenging landscape, new processes, such as Just-in-Time (JIT), are being implemented to meet customer demands in the most efficient way.

How to Successfully Implement Automated Warehouse-Picking Robots

A thorough efficiency analysis might reveal the retailer's item picking process is a severe bottleneck. With that knowledge in mind, it can safely hypothesize how automated order-picking robots could make a big difference.

Reinventing Intralogistics

A comprehensive approach to automation requires networking - not just between the individual components. Because for something really ground-breaking to emerge, already the development must be aligned.

Konoike Transport and OSARO Team Up to Pilot Japan's First Fully Automated Warehouse

Pilot aims to streamline handoff from warehouse inventory robots to picking robots so that businesses can automate and scale-up e-commerce operations despite national manual labor shortage

Invata Rolls Out New Line of Mobile Robotics

The INVATABOTICS fleet will provide enhanced automation processing capabilities to Invata customers in the areas of order fulfillment, returns processing, mobile storage and retrieval, sortation and transportation, and pallet, case, tote, and unit picking.

Important Considerations When Implementing AMR Solutions

When implementing mobile robotics solutions in a facility, it's important to consider strategies for ensuring stability, seamless interaction with people, accurate detection of obstacles, and set up a successful emergency evacuation plan.

The Elimination Tide of Physical Stores: Rise of E-commerce

As retailers forage for new ways to cope, many have decided to close down physical stores and focus on restructuring their business, either through expansion of online retail or introduction of novel business concepts.

Best PC for Smart Warehousing and Logistics - How to Choose

When researching the best PC for smart warehousing and logistics, you might have a specific spec you're trying to meet or processing capability you're looking to achieve. You're also likely looking for a computer that is better, faster and more reliable.

5 MIR1000 Robots Automates the Internal Transportation of Heavy Loads at Florisa

Five autonomous mobile robots (AMR) MiR1000 have improved productivity, safety and eliminated storage problems within the Florisa plant, a company that operates in the textile segment, with production focused on the dyeing of natural and artificial fibers.

Next-Generation Mobile Robots Fleet Management

By collating all the robots onto one platform, we can enable the robots to operate collectively rather than individually. If all the robots are on one platform and under one traffic control, they will be able to share their location and become very efficient.

Warehouses Turn to Automation to Meet Permanent Peak Demand

Supply chains are relying on automation to effectively adapt to fluctuating demand levels, new safety protocols, and shrinking labor pools. The need to operate efficiently, safely, and productively with less people is critical for today and also for success in the future.

How Top Modules Make AMRs Possible

An AMR without a top module is like a robotic arm without an end-effector tool such as a gripper-it lacks functionality. The benefits of AMRs are only realized-and maximized-with top modules and high-quality gates and carts that transfer the transported materials.

Q4 2020 Trend: Immediate Delivery Autonomous Forklifts

Fewer than 2% of forklifts sold in North America are automated, yet there has never been a greater need for this technology. Many manufacturers are looking to automate material handling processes because it reduces the potential for COVID-19 exposure by reducing human contact.

Universal Robots Launches ActiNav, the World's First Autonomous Bin Picking Kit for Machine Tending Applications

ActiNav synchronously handles vision processing, collision-free motion planning and autonomous real-time robot control, eliminating the complexity and risk usually associated with bin picking applications.

Records 1 to 15 of 29

Featured Product

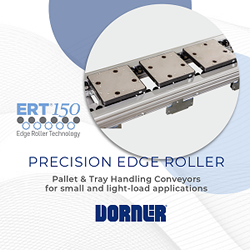

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.

.jpg)