Have you ever wondered how we are able to have an accurate online map to use to get to anywhere we want to go? The answer lies in a process called mobile mapping. Mobile mapping allows users to visualize, record and understand environments, wherever they may be.

Powering Drones with Improved Mobile Mapping Systems

Powering Drones with Improved Mobile Mapping Systems

Case Study from | Parker LORD

Have you ever wondered how we are able to have an accurate online map to use to get to anywhere we want to go? The answer lies in a process called mobile mapping. Mobile mapping allows users to visualize, record and understand environments, wherever they may be. You may have seen vehicles mounted with a camera on their roof roaming around the streets. This is a form of mobile mapping. Mobile mapping can also be used for surveying applications and environmental, transportation and utility mapping.

A Mobile Mapping System consists of a positioning system comprising a GNSS receiver integrated with an Inertial Measurement Unit (IMU). They utilize LiDAR technology, with scanners capable of collecting around 1,000,000 measurements per second. When combined with the GNSS or when using a Simultaneous Localization and Mapping (SLAM) algorithm, these georeferenced data points can be used to create accurate digital terrain models of almost any environment. These units are not limited to cars – they can be mounted to backpacks, helicopters and UAVs.

Revolutionizing Mobile Mapping

Emesent’s Hovermap payload can be attached to drones to allow autonomous mobile mapping in hazardous GPS-denied areas. Parker's inertial sensors enable Hovermap technology by providing precise orientation and velocity information in a small and lightweight package.

“We have stringent requirements for a light-weight, robust and reliable sensor, and Parker's inertial sensors have a proven track record in the autonomy space,” said Dr. Stefan Hrabar, CEO of Emesent. “After more than two years of testing in our prototypes, we were happy with their innovative solution and have built this into the commercial Hovermap payload.”

How does Hovermap work exactly? When mounted to a compatible drone, Hovermap uses data from the LiDAR sensor to enable mapping and advanced autonomy functions. The technology that makes this possible is Simultaneous Localization and Mapping (SLAM). Parker inertial sensors aid the SLAM solution in real time, so a drone can navigate and map a space at the same time, while avoiding collisions. This process lets drones produce accurate renditions of their environment without the need for external services, such as GPS location, which is not always accessible everywhere.

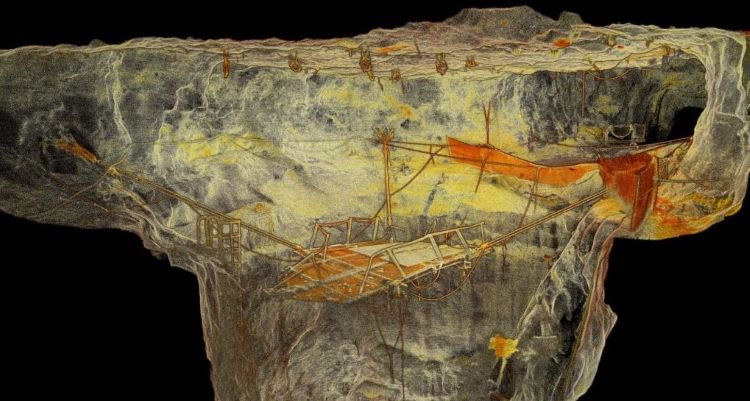

One of the most impressive features of the technology is that the drones use the same data they collect to construct images of caves to locate themselves within the caves. By using SLAM for both navigation and location, both elements are improved – the drones are reliant on collecting accurate data to remain in the air, which means they can stay in the air for longer, and ultimately collect more data to construct more accurate images of the cave systems.

A drone fitted with Emesent’s Hovermap payload also offer significant safety benefits to workers. By removing the need for humans to enter unfamiliar underground areas to complete mapping work, workers are no longer expected to work in these potentially dangerous areas.

The Hovermap-enabled drones are a significant upgrade to conventional cavity monitoring systems (CMS), which are typically used to map underground areas. CMS solutions involve placing a LiDAR at the end of a boom, which is then inserted into cavities. While this enables workers to record LiDAR scans from areas inaccessible to human workers, the technology is limited by physical constraints such as the length of boom and dimensions of the cave. It also still requires the surveyors to work close to dangerous underground areas. CMS scans can have areas of missing data (or shadows), as the scanner only views the cavity from one position. Hovermap on the other hand eliminates shadows as the drone flies around inside the cavity, scanning it from many locations.

“Autonomous drone flight in these challenging GPS-denied environments is no easy task, but is made possible through our advanced algorithms that use the Parker inertial sensor and LiDAR data in real-time.”, explains Dr. Stefan Hrabar, CEO of Emesent. “This technology is a game changer for mining and other industries, providing significant benefits in safety and productivity.”

Resources

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Parker LORD – MicroStrain Sensing Products

Parker LORD - MicroStrain Inertial Sensing Products manufactures the smallest and lightest industrial-grade inertial sensors available that are used in advanced manufacturing, off-highway vehicles, commercial and military manned and unmanned vehicles, and civil structures. Products come temperature compensated using a proprietary calibration process and include inclinometers, vertical reference units, IMUs, AHRS and INS/GPS for navigation, stabilization, mobile mapping, terrain compensation and more. Contact LORD for additional custom designed solutions.

Other Articles

Ways to Improve Your IMU Performance

High Performance Inertial Sensors for Robotic Systems

Benefits of a Tactical Grade IMU in Low-cost GNSS/INS Systems

More about Parker LORD – MicroStrain Sensing Products

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product