Pleora Technologies Expands Distribution in China with New Channel Partner Hongke Technology

With this new relationship, Hongke is distributing Pleora’s industry leading AI, edge processing, and real-time sensor connectivity solutions.

Ottawa, CANADA, August 25th, 2021: Pleora Technologies today announced a new channel partnership with Hongke Technology Co., Ltd., an established distributor of industrial cameras, 3D imaging, and high performance vision solutions in China Market. With this new relationship, Hongke is distributing Pleora's industry leading AI, edge processing, and real-time sensor connectivity solutions.

"China is an important market for Pleora, and with the addition of Hongke we are expanding our presence to better understand and meet the unique needs of designers, system integrators, and end-users in the region," said Brian Chi, Pleora's regional sales manager for China. "Our broad portfolio of real-time sensor connectivity and AI solutions, coupled with Hongke's complimentary technologies and system expertise, will help customers improve quality, maintain brand standards, inspect challenging materials, and automate key points in manufacturing processes."

Designers and integrators rely on Pleora products, system knowledge, and standards expertise to shorten time-to-market, reduce risk, and lower costs. The company's new no-code AI solutions help automate manual processes, improve reliability, and lower the cost of visual quality inspection for consumer goods, automotive, food & beverage, and print & packaging. Pleora's GigE Vision and USB3 Vision sensor interface products, deployed in over 300,000 endpoints in industrial, medical, and security imaging systems, have the capacity to transmit over 30 billion gigabits of data per day.

"We have been successfully rated as the ‘the little giant' of technology innovation, showcasing high-tech products developed by leading companies in the machine vision market," says Lashare Chen, the CEO of Hongke "Our portfolio is expanding rapidly, and we look forward to further strengthening it with Pleora's industry proven product offerings."

About Pleora Technologies

Global manufacturers rely on Pleora's expertise in AI, real-time sensor connectivity, and rugged networking to shorten time-to-market, reduce risk, and lower costs. Established in 2000, the company serves over 1500 active customers in the industrial automation, medical imaging, and security and defense markets. Headquarter in Ottawa Canada, Pleora has 75 employees in research, sales, and support locations in North America, Europe, and Asia. Learn more at pleora.com.

About Hongke Technology Co., Ltd.

Serving over 10 years in the industrial and automotive fields of high-tech, Hongke has been an instrumental part in the distribution of products by multinational suppliers leading the vision market. Headquartered in Guangzhou, China, with locations in Shanghai, Beijing, Taiwan, Hong Kong, and Silicon Valley in the United States, and offices in Xi'an and Chengdu, Hongke range of products includes industrial cameras, 3D and 10GigE cameras, 3D solid-state LiDAR, vision software platform, frame grabbers and other vision solutions.

Featured Product

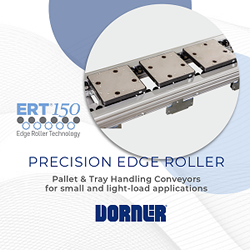

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.